Industry UpdateFebruary 22, 2021

Dropship Print on Demand Trends that will Increase Profits

Industry Update

When it comes to dropship print on demand trends, drinkware is the first product that comes to mind. There are so many reasons why drinkware is the hottest product of the decade. These include, the ability to recreate original art on a new canvas, the need for a reduction in single-use plastics and its ability to keep your favorite drink at the perfect drinking temperature longer.

Read more about why print on demand drinkware should be added to your product mix.

At this point, you’ve decided that drinkware is your product of choice for your creators. The discussion turns now to how can you take this trend and become profitable from it? Of course, there are the obvious reductions to costs and increases in margins that you can work on but what if there was a way to make your drinkware products so unique, your customers will be throwing orders at you? That is where dropship print on demand digital printing comes in.

Dropship Print on Demand Drinkware: Digital vs. Dye-Sublimation

First things first, which method of printing will give you the greats ROI. For the purpose of this article, we will compare digital printing and sublimation. Many are familiar with the dye-sublimation as it is the process of choice for products such as coffee mugs. With this process (and taking coffee mugs as the example), the artwork is first printed on sublimation paper and then heat transferred onto the coffee mug. Once complete, this yields a beautifully printed product. Unfortunately, some of the draw backs include the overwhelming amount of waste this process produces, the inability to adhere to anything but polyester and the speed of this process. Dropship print on demand digital printing offers a whole new perspective. Digital printing is a computer-to-product method where the artwork is digitally sent to the printing machine and printing directly onto the product- practically any product. From stainless tumblers to high-end water bottles to glassware, digital printing offers amazing quality graphics at a lower cost and higher speed.

Digital Dropship Print on Demand Trends

Digital printing offers numerous design techniques that will have your customers flocking to your store. These design techniques are unique to this process of printing only and are a top differentiating factor.

Full Coverage

Full coverage refers to how the artwork is printed. With digital printing, artwork can be printed without a seam and the full length of a bottle (up to 8.6”). This method is difficult to achieve with dye-sublimation as the artwork has to be manually lined up on the product in order to achieve a seamless graphic. With digital printing, it is setup in the program.

Mirror Print

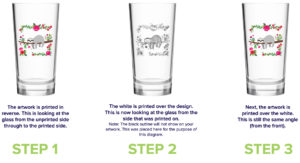

With digital printing, a white layer is printed behind the full-color layer to make it pop on clear or dark surfaces. Printing this layer on a white product is unnecessary since the product’s color can act as this background. With transparent products such as pint glasses, wine glasses and stemless wine glasses, see the white through the glass is just not appeasing. To solve this issue, mirror printing was invented. How it works is simple: the machine prints the graphic with the full-color graphic facing inwards and the white facing outward. If you were to remove the product from the machine at this point, you would think your artwork was printing in reverse. Once that has been printed, the machine then prints the full-color artwork over the white, facing outward. The result is a beautifully decorated piece with artwork that can be seen from the inside and outside of the product.

In addition to simply copying the graphic, this feature also gives you the ability to hide a message. From the outside, you may see a simple graphic but while drinking out of the glassware piece, others are seeing a funny message or graphic from the inside.

Etched and Stained Glass

Sticking on the subject of glassware, reproducing an etched or stained-glass look are both absolutely achievable with digital printing. Many pint glasses that you see on the market are etched with a laser to give it a classic bar look. Digital printing will astound you with the capabilities of matching this style but without the engraving. By utilizing white at a lower opacity, a pint glass can look as if it were etching with a laser.

Stained-glass takes the opposite approach. Instead of using white at a lower opacity, this design technique uses a lower opacity color to create artwork that is slightly see through. You can apply this to the entire artwork or just parts. Either way, it is a unique design that isn’t available for any other printing method.

Tone on Tone

Switching from glassware to any product is a method called tone on tone. Tone on tone uses only varnish to highlight the features of the product itself. When printing varnish only on a matte black bottle, you are able to create a one-of-a-kind look that doesn’t require a full coverage graphic.

Spot Varnish

Spot varnish is a method of printing that highlights small aspects of the graphic itself with an additional layer of varnish which makes it shine. Varnish is a clear coating that is used to make graphics glisten. This does not affect the durability of the product, rather it is only a design element that some consumers prefer, and others do not. Spot varnish adds a slight touch of shine to make it stand out from other products.

Matte

If you are not looking for any shininess, then you can simply go without the shine. Remove the varnish layer from the artwork allows you to print a sleek, matte look. This is especially impressive when mixed with other design techniques.

How do these design techniques help increase profits?

Getting to the bottom line, these design techniques help increase profits because there is simply no other technology out there that can achieve these. There are so many dye-sublimated products out there that may be differentiated due to the graphics but there are no print elements that can make one product stand out from another. An artist is looking for the best way to make their artwork shine, so offering the ability to not only recreate their amazing art on a new product but also offer unique design techniques that will make their vision come to life even further is incredible. Choosing digital for your dropship print on demand drinkware is the best solution for product differentiation and overall sustainability.

I want all these printing methods! How can I achieve them?

This is simple! Contact Digital on Demand for full-service drinkware print on demand drop shipping. Digital on Demand’s simple API connects to major eCommerce platforms. Choose from our line-up of sourced print on demand products. Digital on Demand uses Helix® Technology to achieve these amazing graphics.

Contact us to get started!

Back to Blog Home

Add Your Comment